CoroMill® MS40

The ultimate tangential milling solution

Robust design with trusted power

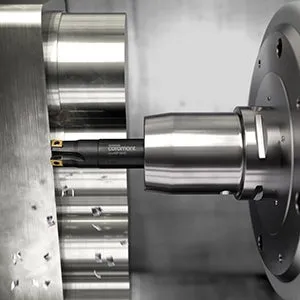

CoroMill® MS40 is engineered with tangentially mounted inserts, maximizing the core strength of the tool body. Its design ensures effortless machining of the most demanding face and shoulder milling applications.

Side milling perfected

Designed as a true 90-degree cutter, CoroMill® MS40 offers accurate and reliable side milling and repeated passes. The outcome is flawless walls with precise dimensions, minimal roughness and perfect perpendicularity.

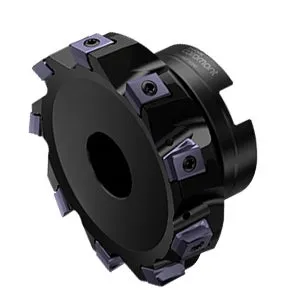

Four-edged stability

Optimized geometries ensure high performance and long insert tool life. The inserts are easy to index thanks to the side-access screw and offer flank edge relief independence from the main support face.

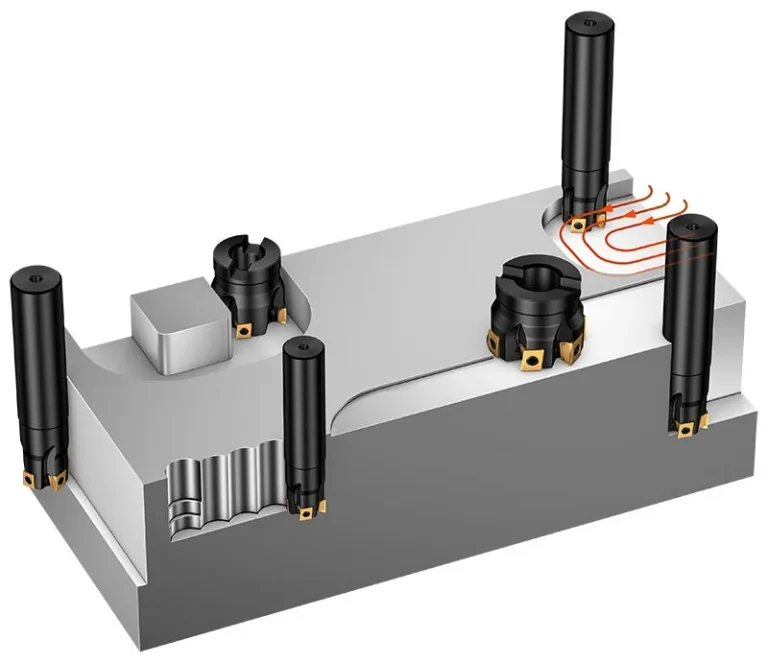

Application

- Optimized for true 90-degree shoulder milling and repeated passes in side milling

- The secondary application areas are face milling, full slot milling and plunge milling

- For roughing and finishing operations

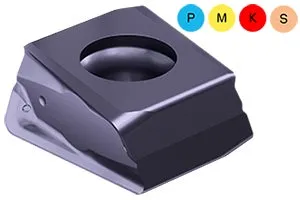

ISO application areas

![]() Steel

Steel

![]() Stainless steel

Stainless steel

![]() Cast iron

Cast iron

![]() Heat resistant super alloys

Heat resistant super alloys

Product Range

Cutter body, cylindrical shank

- Diameter range 25–32 mm (1–1¼ inch)

- M (differential) and H (even) pitch

- Maximum depth of cut: 8 mm (0.315 inch)

- Internal coolant

Cutter body, arbor

- Diameter range 40–160 mm (1½–6 inch)

- M (differential) and H (even) pitch

- Maximum depth of cut: 8–12 mm (0.315–0.472 inch)

- Internal coolant up to Ø125 mm (5 inch)

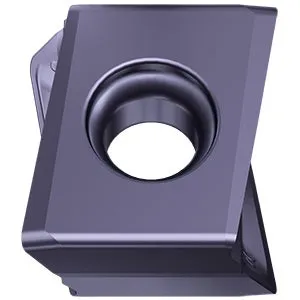

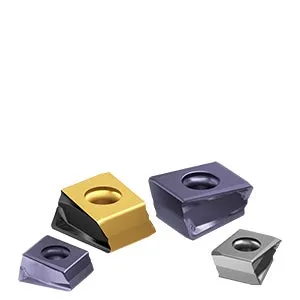

Inserts

- Insert sizes: 09 and 13

- Entering angle: true 90º

- Maximum depth of cut: 8–12 mm (0.315–0.472 inch)

- Recommended depth of cut: 2.5–4 mm (0.098–0.157 inch)

- Corner radius: 0.4–0.8 mm (0.0157–0.0315 inch)

Insert geometries

E-L30 (SSC 09)

E-L40 (SSC 13)

Periphery-ground geometry

- Light-cutting geometry

- Tighter tolerance ensures better component quality and longer insert tool life

- Regulates chip formation and evacuation in sticky, long-chipping materials

- Optimized geometry for ISO M, stainless steel applications

- Good edge-line security and trouble-free machining at long overhangs

E-M40 (SSC 09) (ISO P, M, K, S)

E-M50 (SSC 13) (ISO P, M, S)

Periphery-ground geometry

- Versatile geometry for all kinds of material

- Preferred geometry for roughing in austenitic stainless steel materials

- Ground-reinforced edge for predictable and gradual wear characteristics

- Tighter tolerance ensures better component quality and longer insert tool life

M-M40 (SSC 09)

M-M50 (SSC 13)

Direct-pressed geometry

- Reinforced geometry for medium and heavy-duty applications in ISO P and K

- Strong radius for higher security around corners

- Highest metal removal rate in stable applications

Highlights

Demo: CoroMill® MS40

See CoroMill® MS40 in action and discover why it is the ultimate tangential milling solution.

Metal cutting knowledge: Milling

This section covers application knowledge and tips for various milling operations. Brush up on your milling knowledge.

90% productivity increase

See how a customer solved the challenge of production ramp up by using CoroMill® MS40.